But it's not about Newton. So you want to be sure, in the equipment, equipment that you use!

They will make sure of reliability, various markings, calculation terms, standards that are driven into the framework help, allow the use of equipment within the permissible limits, of course, if there is no goal, destroy something, break something.

In order for the element of our equipment to be published, in other words, fell into our hands, we carry out a series of various tests. One of the calculated values obtained by testing is the ProofLoad (PL) test load. PL is the ultimate load applied to determine whether the equipment item (equipment) has a permanent deformation after this load at a specified time. Thus, the result of the test load can theoretically be related to the characteristics of the equipment element under test in accordance with the expected operating conditions. For example, on the anchor bolt the test load 6 kN (in accordance with the BS 7883 standard). Under this load, the anchor bolt should not receive deformations that violate its functional properties, otherwise use may lead to consequences that are inconsistent with safe operation. Directly on the product, the PL marking may not be indicated, but the main thing is not to forget, to help us with the standards (ENs)

But the marking of MBS, firms manufacturers of equipment for rope access more often point to products, also in conformity certificates, unit of measurement kN.

Minimum Breaking Strength (MBS) is the minimum stress on the tear, this marking indicates the minimum breaking load, the impact of which on the equipment element can lead to its destruction.

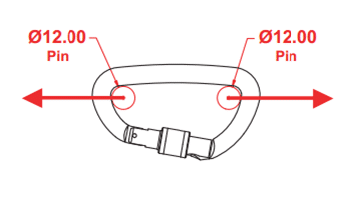

The main thing to remember is that the MBS installed by the manufacturer is indicated exclusively for new equipment. Provided that we used some equipment well, it is worth considering the percentage of equipment degradation. For example, the influence of ultraviolet radiation and organic matter on nylon equipment. We can learn the MBS requirements for the equipment we use from the standards. For example, you can take carabiners, in the requirements for connecting elements, in the EN 362 standard, the minimum breaking load ↔ 20 kN. The carabiner stretches longitudinally between two 12mm diameter pins, with a closed carabiner latch, as tested by UIAA.

The main thing to remember is that the MBS installed by the manufacturer is indicated exclusively for new equipment. Provided that we used some equipment well, it is worth considering the percentage of equipment degradation. For example, the influence of ultraviolet radiation and organic matter on nylon equipment. We can learn the MBS requirements for the equipment we use from the standards. For example, you can take carabiners, in the requirements for connecting elements, in the EN 362 standard, the minimum breaking load ↔ 20 kN. The carabiner stretches longitudinally between two 12mm diameter pins, with a closed carabiner latch, as tested by UIAA.

There are two more accompanying markings, which I wanted to examine in more detail: SWL and WLL.

I would like to first consider WLL (WorkingLoadLimit) that in Russian sounds like the ultimate workload. The WLL marking is usually installed by the manufacturer in order to protect the equipment element, our own equipment, from extreme loads that lead to permanent deformation, severe fatigue, and sometimes invisible changes in the properties of the materials that make up the equipment. WLL is a value, we can say the manufacturer's recommendation, the normal use of equipment. For example, for carbines, the maximum workload will be about 4 times less than its MBS value, if you give the load a higher WLL value, then it should not be surprising why you can not unscrew the carbine clutch by hand.

SafeWorkingLoad (SWL) is a safe workload that is determined under specific conditions, taking into account the strength factor (SF). The same (SafetyFactor) safety factor depends on what equipment we use, or rather from what material is manufactured. In accordance with this, in the sphere of rope access, SF for metal products 5: 1, and for products made of 10 nylon: 1. In this case, SafeWorkingLoad (SWL) can be installed by the hardware manufacturer, or be calculated by the end user based on the MBS-based usage configuration.

SWL = MBS / SF

For example: We need to calculate the SWL for a self-made loop (highly not recommended), from a 6 mm cord and the junction is tied with a grapevine knot. MBS of the cord is declared by the manufacturer 1200 kg, we subtract 30% from this value - this is the loss of strength due to knots and that 840 kg and taking into account SF = 10 for nylon we get 840/10 * 2 = 168 kg

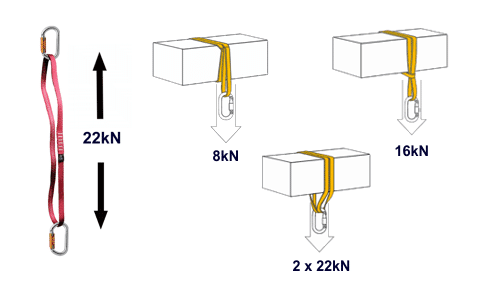

But you can not miss the point that the safe workload is determined in specific conditions, that is, depending on the configuration of the use of equipment. For example, in the figure, initially SWL sling 22 kN, but depending on the use in a particular configuration, the safe workload also changes.

But you can not miss the point that the safe workload is determined in specific conditions, that is, depending on the configuration of the use of equipment. For example, in the figure, initially SWL sling 22 kN, but depending on the use in a particular configuration, the safe workload also changes.

All these abbreviations SWL, WLL, MBS, PL - help us correctly, and the main thing is safe for us and others to use equipment in our very interesting and diverse activities.

And do not forget to read the manufacturer's instructions to know everything about the equipment / equipment with which you work!

Source: http://blog.safework4you.com

Tracers stunt harnesses and safety equipment

Tracers stunt harnesses and safety equipment