METHODS OF EQUIPMENT DISINFECTION

This article contains information which helps to choose right method for harnesses disinfection that meets your needs without being harmful to your equipment.

With present situation related to Covid-19 many of our clients began to use sanitizers to keep their equipment safe and clean before and after use. But due to different compositions used in sanitizers we need to understand what chemicals are harmful for what kind of fibers.

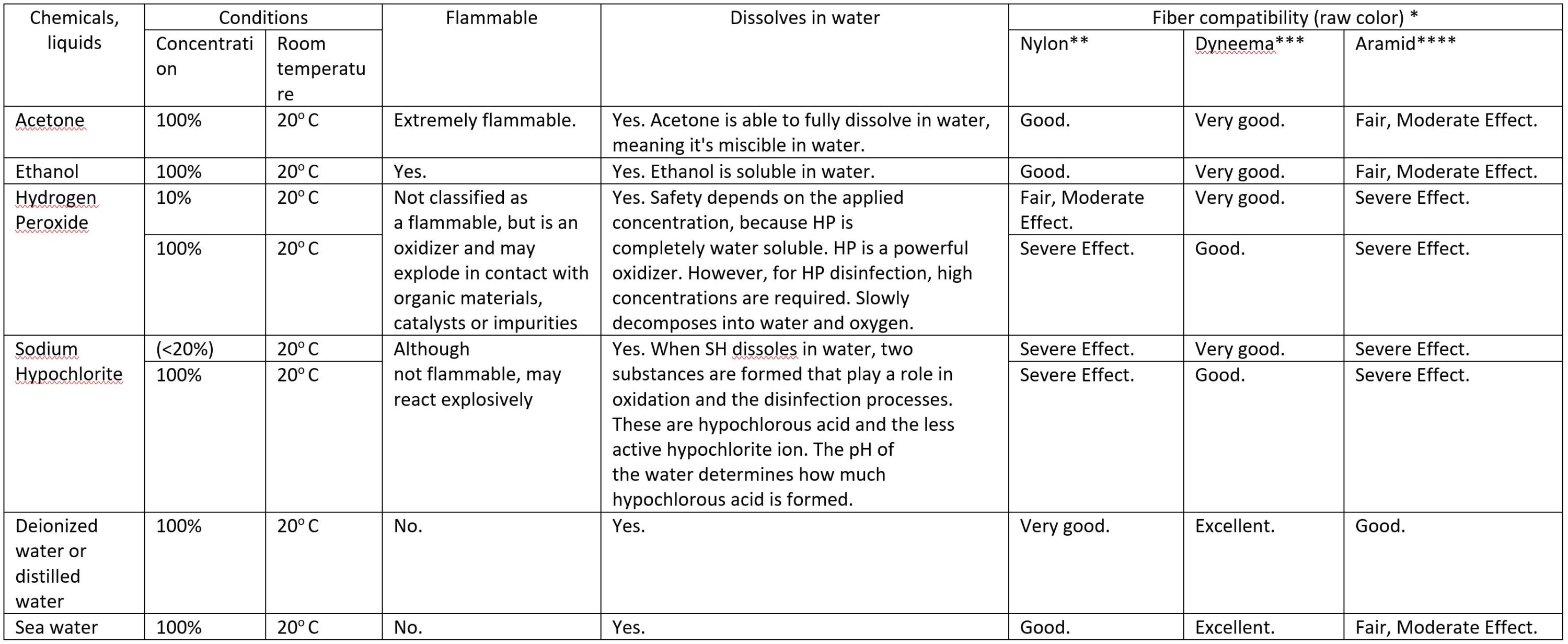

Here at Tracers we have gathered different researches and combined in this article. Here is the table showing most used chemicals in sanitizers and their effect on different types of fibers:

* ALL info in table is a result of tests applied on dried naturally RAW COLOR fibers. Even if some chemicals from this table does not affect tear strength they still can and most of the time will more or less affect dying. Harness or other products can loose its color after disinfection or cleaning even with fiber compatible liquids.

** Please refer to Nylon when you are using: nylon stunt vests, nylon fall-arrest harnesses, nylon climbing ropes, nylon belts and webbing.

*** Please refer to Dyneema when you are using: stunt vests made of Dyneema or Spectra, Dyneema/UHMWPE ropes, Dyneema loops and webbing.

**** Please refer to Aramid when you are using: fire proof harnesses, Tech12 Technora ropes, other aramid ropes and webbing. Special coating can protect fibers.

ALWAYS AVOID BLEACH! To avoid loosing color choose the best cleaning method which is hand wash in not more than 30o C water.

This table is for general information only. The best way to be sure in sanitizer composition is to make it by yourself. Be very careful and don’t give your equipment for disinfection or for any other procedures to wardrobe department or anybody else.

INFORMATION IN TABLE BASED ON RESEARCHES OF MGSU LAB, CHEMICAL FIBERS COMPATIBILITY RESEARCHES.

SANITIZERS IMPACT ON FIBERS

Research by Teufelberger.

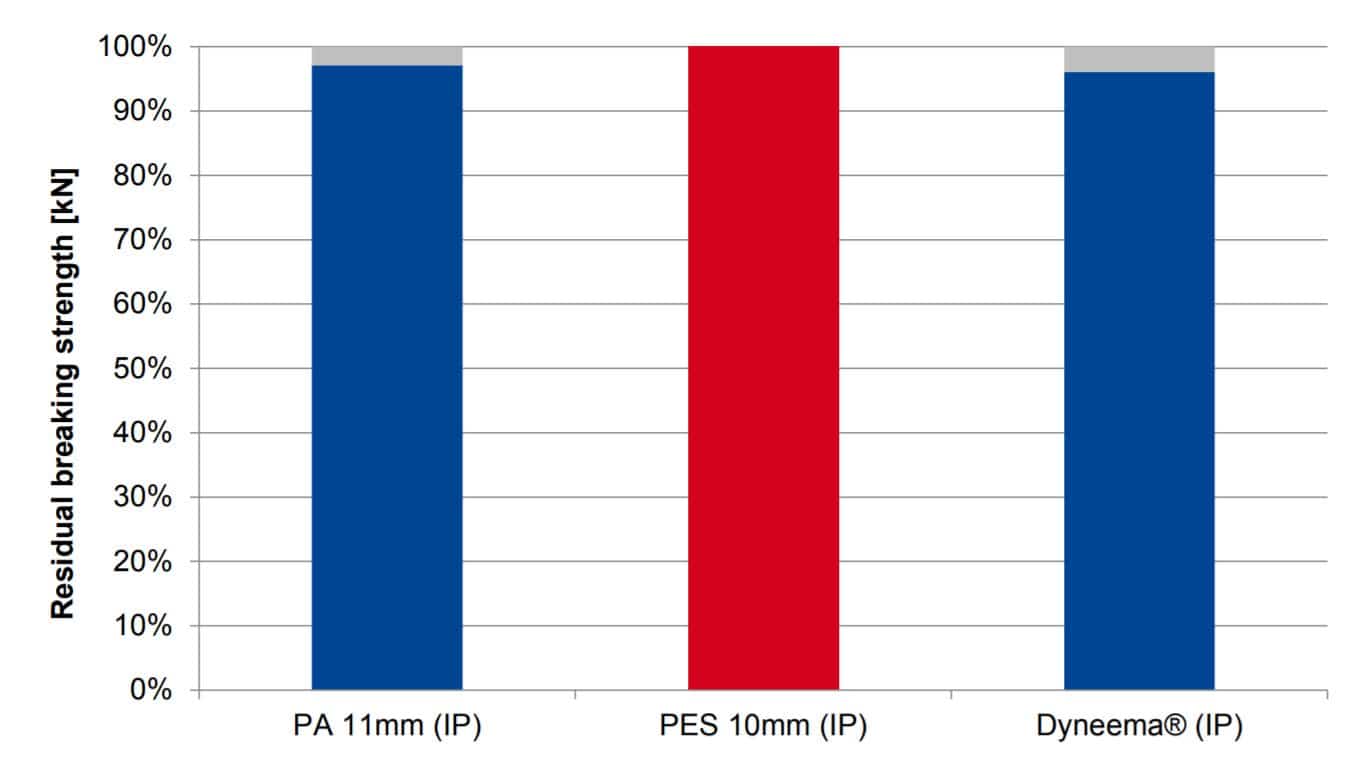

In 2015, TEUFELBERGER, the global rope manufacturer and parent company of MAXIM climbing ropes, ROBLINE and NEW ENGLAND ROPES marine ropes, conducted a study about “Deliberate Damage of Ropes”. In this study, we tested the impact of different kinds of soiling, washing and abrasion on the rope’s breaking strength. In the arborist business, for example, it is a normal course of business to disinfect the equipment after working in pestinfested regions.

Therefore, as a part of the study, the impact of disinfection was also tested. In light of the recent developments with to the Corona Virus, we would like to recall these results and share them with you. In the study we tested ropes made of different materials (Nylon, Polyester, Dyneema®). The ropes were disinfected one time by being submerged in a solution of 70% Isopropanol and 30% distilled water for 3 minutes and then left to air dry naturally for 48 hours before being tested for their residual strength.

The results show, that there has been no decrease in breaking strength for Polyester ropes, and only 2-4% decrease for other ropes tested. However, we did note that the hand and flexibility of the rope does deteriorate after the disinfection.

Based on these results, from TEUFELBERGER’s perspective, it is acceptable to disinfect your ropes in this manner.

We recommend the following when disinfection ropes:

- Ropes can be disinfected by being submerged in a solution of 70% Isopropanol and 30% Distilled Water for 3 minutes maximum.

- Air dry the ropes naturally away from heat source or direct sunlight

- The Safety rules provided on the safety data sheet should be followed for all other rope care

- Disinfection should be done when needed and not daily – the long term impact is being tested. A qualified inspection of the rope is mandatory.

This Data applies to the disinfection of the ropes themselves and does not make any recommendations as to any other procedures or policies for preventing infection in other areas.

Since the impact of Covid-19 is still being studied and further understood, this study represents a point in time test. We are continuing to test and will update this document as new data becomes available.

UV DEGRADATION OF NYLON FIBERS

Research by Gigi Signoretti Commission for Materials and Techniques, Italian Alpine Club.

Ropes and sunlight: a matter of … colour

Exposure of nylon ropes to the sun causes an irreversible deterioration of their physical and mechanical properties due to reactions induced by UV radiation. Photo-oxidation modifies the chemical structure of the nylon macromolecules, since it initiates their de-polymerisation, which leads to loss of resistance and elasticity of the material. This process can be reproduced in laboratory using a suitable artificial light.

It is possible to reduce these reactions by means of photo-chemical stabilization of the nylon fibres; this can be accomplished using either UV protecting agents similar to those used in sun creams (products that act as filters for a radiation of specific wavelengths), or anti-oxidation products.

These processes – photo degradation of nylon and its stabilization – have been well studied, but it is still very difficult to clearly anticipate their development. Particularly on materials used for mountaineering knowledge is very scarce, so that mountaineers cannot answer questions such as: How big is the reduction of the mechanical characteristics of the core and sheath of a rope due to sunlight, as a function of usage? What is the influence of this degradation in terms of resistance to wear and dynamic behaviour of the rope ?

Laboratory experiments

Ropes of five different makes, chosen among the most commonly used, where exposed to artificial light as well as to natural sunlight.

The exposure to artificial light was performed by means of an apparatus usually employed in specialised laboratories to produce accelerated photo chemical degradation, the so called xenotest. This apparatus contains a xenon lamp, which produces a radiation spectrum nearly identical to the solar one; its radiation flux is about 10 times that obtained by natural sunlight at sea level.

Experiments in-the-field

Exposure to natural sunlight occurred:

– at an altitude of 2550 m, on a wall of the Kostner hut in Vallon (Sella

group)

– at an altitude of 1843 m, on a wall of the Carestiato hut (Moiazza group)

Two representative places in the Dolomites area, very popular with mountaineers.

Synthesis of the results

Colour degradation.

The following general remarks apply:

– ropes decolourise much more rapidly under irradiation with the xenon lamp

than under natural sunlight;

– on some ropes all colours fade uniformly whereas on other types of rope some

colours remain stable and others disappear nearly completely;

– the ropes exposed at 2550 m on the Kostner hut lost more colour compared to

those exposed at 1834 m on the Carestiato hut.

Decay in mechanical properties of the filaments. A correlation was found as expected – between the fading of colour and the mechanical properties of the filaments: the higher the loss of colour, the higher the degradation of the mechanical characteristics. This seems to concern mainly the brilliant colours and the colours a-la-mode, say acid green and fuchsia. This may be caused by either a rather vaguely described catalytic action due to the chemical structure of the colour itself, a process mentioned in literature, or by the reduction of the filtering action of the colour against UV.

Core and sheath.

The degradation of filaments due to UV radiation is more contained and more uniform throughout the core than in the sheath, irrespective of the type of exposure (sun/rain or xenotest). The larger sensitivity of the sheath fibres to radiation is due not only to the direct exposure to the sun but also, as already mentioned, to the characteristics of the colours present on the fibres. As for the speed of photo degradation, it can be stated that one day exposure to xenon lamp is equivalent to about 5 to 10 days exposure to sunlight (see plots of Figs 1a and 1b). Degradation of the filaments and dynamic performance of the rope. The obvious question of a mountaineer is, at this stage, how the degradation of the mechanical characteristics of the filaments affects the dynamic performance of a rope, i.e. the number of falls held on the Dodero. Remarkable scattering of the data, shows a clear tendency: a relatively low degradation of the mechanical properties of the filaments (e.g. 10%) is sufficient to generate a large reduction in the number of falls (say 50%).

SUMMARY

Please read and understand all information above on this page.

Here below we suggest solutions for harness disinfection:

Disinfection with UV lamp (lamp is available for purchase on tracers.ru)

UV lamp is good option to use for harness disinfection if disinfection is really needed. UV lamp should be placed not closer than 1m distance to object for disinfection. 1 min disinfection is enough when distance from lamp to object is 1 meter.

UV lamp can be used with Nylon, Polyester and Dyneema equipment.

As for the speed of photo degradation, it can be stated that one day of Nylon exposure to xenon lamp is equivalent to about 5 to 10 days exposure to sunlight.

Decay in mechanical properties of the filaments. A correlation was found as expected – between the fading of colour and the mechanical properties of the filaments: the higher the loss of colour, the higher the degradation of the mechanical characteristics.

Sanitizer (make it yourself or buy from approved supplier)

If for some reason you don’t to use UV lamp for harness disinfection you can use mix of 70% Isopropanol and 30% Distilled Water prepared by yourself from approved ingredients. Spray it to the disinfected piece (just spray, do not rub) of equipment and let it dry naturally. This method is more harmful compared to UV lamp but still can be used.

Sanitizer composition: 70% Isopropanol and 30% distilled water.

The results show after soaking sanitizer composition for 3 minutes, that there has been no decrease in breaking strength for Polyester ropes, and only 2-4% decrease for Nylon and Dyneema. However, we did note that the hand and flexibility of the rope does deteriorate after the disinfection.

If you have any questions about materials, fibers or about harness inspection then please let us know.

MATERIALS USED FOR THIS ARTICLE

Covid-19 (Corona Virus) Rope disinfection by Austrian rope manufacturer Teufelberger

Tracers stunt harnesses and safety equipment

Tracers stunt harnesses and safety equipment